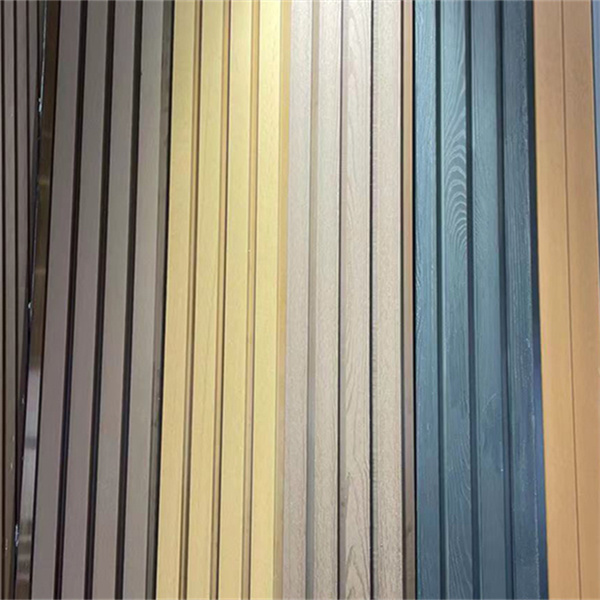

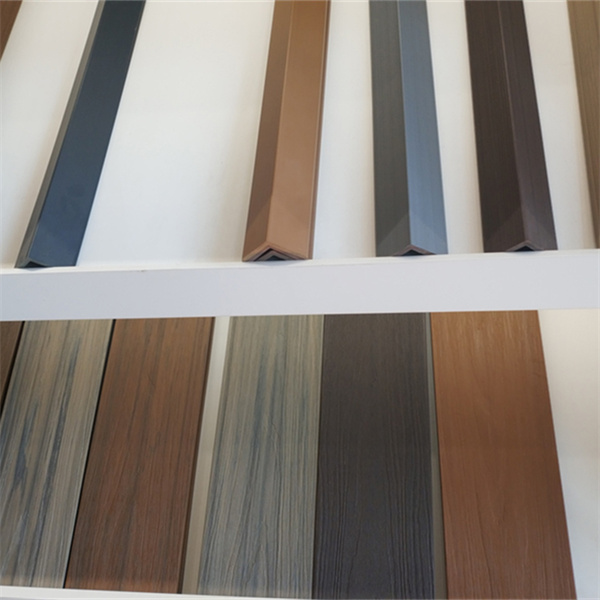

PE wood plastic material has excellent waterproof and anti-corrosion properties, high hardness, and is subject to thermal deformation and buckling, but the thickened or porous hollow structure has good effect.1. The product has a limited life span for outdoor use; It is currently used for 3-5 years; 2. The oxidation resistance and light decomposition resistance are poor. Even if the anti oxygen agent and UV reference agent are added, the effect is not ideal, and the product strength and color fastness will also be affected; 3. The appearance of the product is pure in color, without woodiness, and the appearance effect is poor.1. PVC wood plastic products can be made of new materials or old materials (while PE products made of new materials are too expensive to enter the market). It is also easier to modify, and the amount of supplement depends on the production and quality; 2. PVC can be made into low foaming wood plastic products, so the cost is lower. Co extrusion (double material multi material co extrusion or steel plastic co extrusion) can be used if it is appropriate, and the strength and wood grain feel are good; 3. PVC can be used for secondary processing of various surface patterns or paint covering UV paint, and the product is good-looking and has good color fastness; 4. The waterproof and anti-corrosion properties of PVC wood plastic products are also excellent.

PE wood plastic material has excellent waterproof and anti-corrosion properties, high hardness, and is subject to thermal deformation and buckling, but the thickened or porous hollow structure has good effect.1. The product has a limited life span for outdoor use; It is currently used for 3-5 years; 2. The oxidation resistance and light decomposition resistance are poor. Even if the anti oxygen agent and UV reference agent are added, the effect is not ideal, and the product strength and color fastness will also be affected; 3. The appearance of the product is pure in color, without woodiness, and the appearance effect is poor.1. PVC wood plastic products can be made of new materials or old materials (while PE products made of new materials are too expensive to enter the market). It is also easier to modify, and the amount of supplement depends on the production and quality; 2. PVC can be made into low foaming wood plastic products, so the cost is lower. Co extrusion (double material multi material co extrusion or steel plastic co extrusion) can be used if it is appropriate, and the strength and wood grain feel are good; 3. PVC can be used for secondary processing of various surface patterns or paint covering UV paint, and the product is good-looking and has good color fastness; 4. The waterproof and anti-corrosion properties of PVC wood plastic products are also excellent.